You'd think that the supply chain world would have adjusted to a new normal by now, but the virus keeps proving us wrong. From a shortage of glass vials for testing to a reduction in food demands as restaurants close again, the national and global supply chain keeps changing in perilous ways. How do businesses need to adapt?

Running Down the Most Recent Shortages

The thing about the pandemic era is that some of the shortages you might expect—and some you might not. What’s more, factories across the world are continually ramping up and down in response to these shortages, which means keeping track of them represents a moving target. Here are a few things that we’re running out of unexpectedly:

- Syringes

We’re not running out of syringes right now—but we might be soon. The world is moving closer and closer to a vaccine for COVID-19, but creating the vaccine might be the easy part. The real challenge will be inoculating billions of people, which will push the world’s supply of hypodermic needles to the breaking point. - Laptops

Computer equipment suppliers have been caught between two computing demands. First, everyone who suddenly needed to work from home in March either bought a laptop or was given one by their company. Next, every student who started distance learning was given a laptop by their parents or school district. As such, the three major laptop manufacturers have reported that they are behind on nearly five million orders. - Coins

You may have seen Facebook posts and signs in shop windows saying that the US is experiencing a coin shortage—and this isn’t hyperbole. Bank branches are closed or experiencing reduced hours, and the US Mint resumed normal operations only a few months ago. This means that there aren’t enough coins in circulation to meet demand. You can do your part by paying for any purchases with credit cards or exact change and taking any spare change to your nearest Coinstar machine. - Plastics

Here’s some anecdotal data from AFFLINK—plastics have been hard to keep in stock. This mostly includes disposable items such as gloves, trash bags, pump bottles, and more. Many more people now need disposable gloves, so it’s not necessarily surprising that they’re hard to find. Meanwhile, people staying at home generate more waste, which explains the shortage of trash bags.

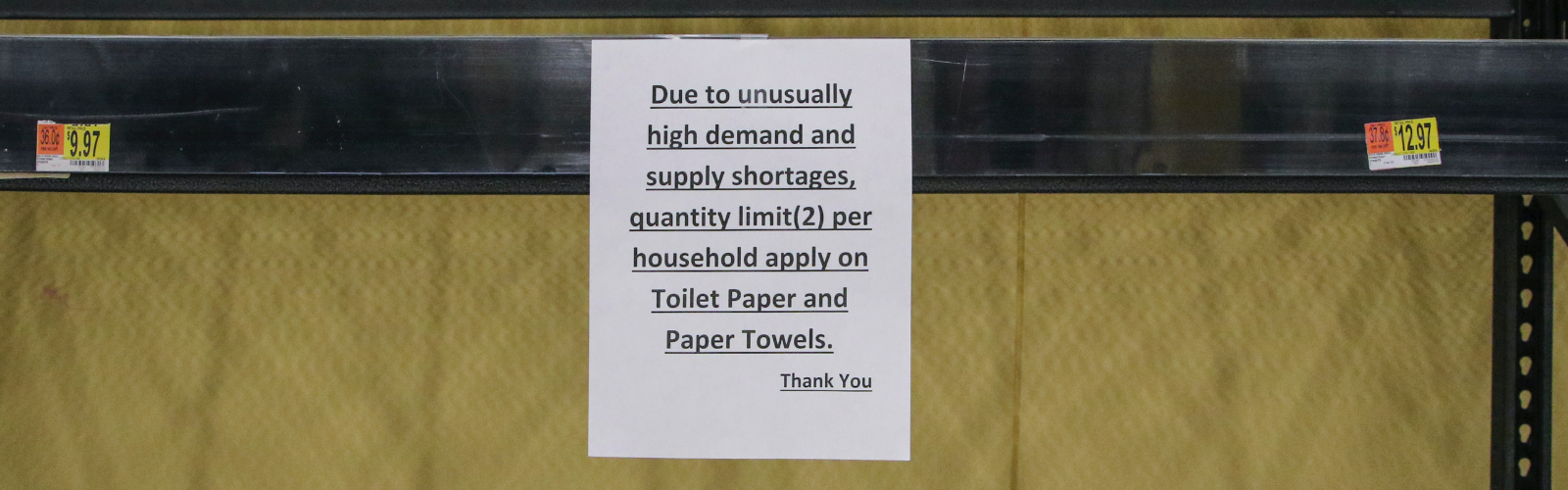

COVID-19 has exposed many supply chain weaknesses. Only about 25% of manufacturers and businesses have flexible supply chains. The rest are relatively entrenched—there’s no backup plan if they suddenly don’t have a place to buy toilet paper, for instance.

Here at AFFLINK, we make sure that businesses always have a place to purchase essentials. We work directly with major suppliers to ensure that companies can purchase the staples they need in the quantities they need at the right price. For more information about working with us and creating a flexible supply chain for your business, contact AFFLINK today!

About Michael Wilson

Michael Wilson is AFFLINK'S Vice President of Marketing and Communications. He has been with the organization since 2005 and provides strategic leadership for the entire supply chain team. In his free time, Michael enjoys working with the Wounded Warrior Project, fishing, and improving his cooking skills.