No matter what type of business you’re in, it seems as if there are always a few topics that are so trendy you get tired of hearing about them: lean manufacturing, Internet of Things, sustainability, and other causes célèbre. But it’s important to remember that, most of the time, there’s a reason everybody is talking about those topics. The real industry experts – the ones who are tied into the pulse of what’s coming next – know that those trends are going to change the way they do business.

No matter what type of business you’re in, it seems as if there are always a few topics that are so trendy you get tired of hearing about them: lean manufacturing, Internet of Things, sustainability, and other causes célèbre. But it’s important to remember that, most of the time, there’s a reason everybody is talking about those topics. The real industry experts – the ones who are tied into the pulse of what’s coming next – know that those trends are going to change the way they do business.

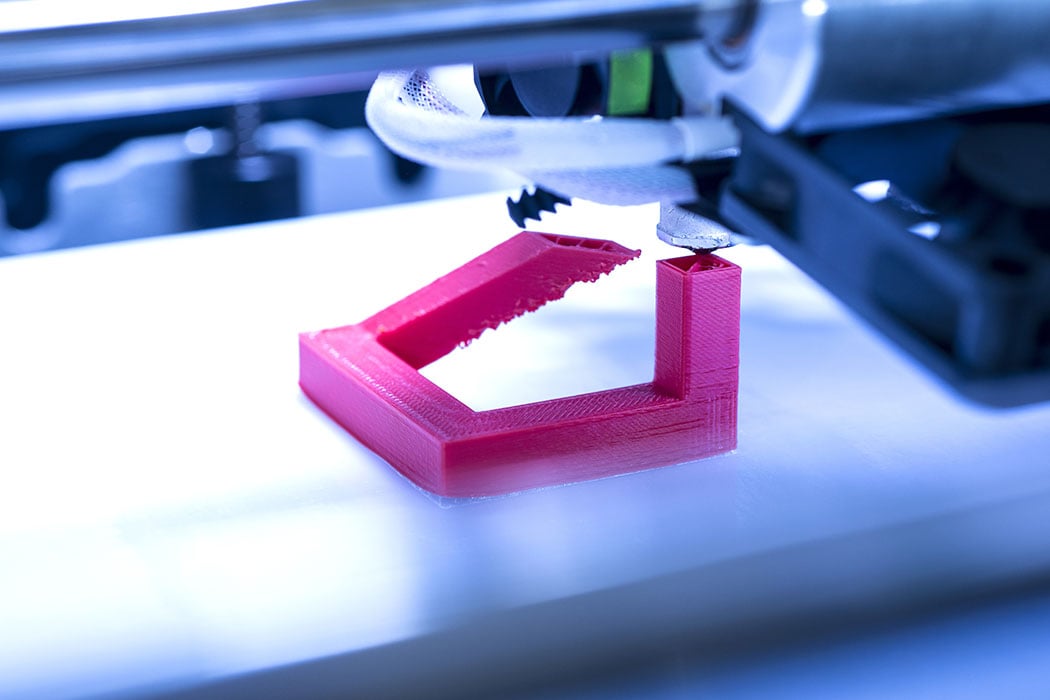

One such “trendy” topic is 3D printing. Everybody’s talking about it so much that you may be tempted to tune it out – but don’t, especially if you’re responsible for procurement management. Because of 3D printing, the supply chain world is likely to look very different in five years than it does now. Here are some of the things we see coming:

1. Less Push, More Pull

Most businesses involved in mass production operate on a “push” model. Because profitability depends, in part, on optimizing economies of scale, they produce a whole lot of something and hope people will buy it. Thanks to predictive analytics, demand forecasts can be amazingly accurate, but there’s always the risk that the economy will take a downturn or that customers will turn their noses up for some reason you didn’t envision, leaving the product sitting on the shelf. Another drawback involves the cost of stocking raw materials and the value of materials in progress. 3D printing promises to solve some of those challenges by ushering in an era of on-demand manufacturing. Any savings lost by giving up economies of scale can be recouped further down the supply chain.

2. Localization

The “buy local” movement has skyrocketed in recent years, but it’s been limited primarily to food production. 3D printing has the potential to expand “buy local” to an almost unlimited array of products. Freed of the need to gain economies of scale through centralized production, manufacturers can have smaller facilities near their end users, reducing shipping costs and augmenting sustainability initiatives.

3D printing isn’t all fun and games, however. While most businesses certainly have the opportunity to benefit from 3D printing, there are a few challenges, too.

3. Logistics

Widespread implementation of 3D printing could necessitate a total revamp of procurement management and transportation models. For example, if localized distribution centers become commonplace, will trains and heavy trucks still be the most efficient means of transportation? Or will other methods, like drones or an Uber-style network of personal automobiles make more sense? What will distribution in a world of personal customization, on-demand production, and instant gratification look like?

4. Contingency Planning

Smart businesses have a plan for what to do if something goes wrong. Traditionally, that has meant storing backups for essential parts used in the manufacturing process. How will that change when parts can be printed on demand? How can that newly available space be optimized? Or will the downtime be too costly; making as-needed printing of replacement parts an impractical solution?

5. Legal Uncertainties

In terms of 3D printing, there are still a lot of unanswered questions when it comes to intellectual property rights. When a business prints an object, it has to think about who owns the design for that object. That’s something that can be worked out through vendor agreements, but it’s new ground for all of the stakeholders. Instead of buying and selling physical goods, they’ll be buying and selling the rights to use a design. Businesses will have to figure out details such as whether designs will be bought and sold, licensed on a per-use or batch basis, etc.

While the details may still be unclear, what’s certain is that 3D printing will play a major role in procurement management, and all supply chain professionals will need to adapt or be left behind. How might 3D printing disrupt – or enhance – your supply chain?

About Michael Wilson

Michael Wilson is AFFLINK'S Vice President of Marketing and Communications. He has been with the organization since 2005 and provides strategic leadership for the entire supply chain team. In his free time, Michael enjoys working with the Wounded Warrior Project, fishing, and improving his cooking skills.