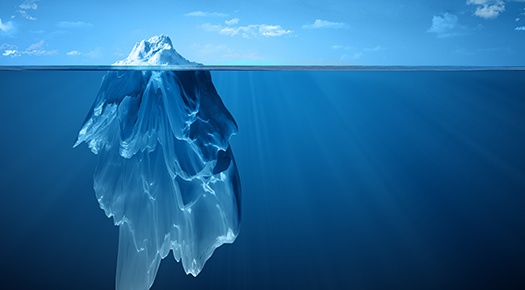

Too many organizations see the supply chain as a necessary cost of doing business, failing to recognize that it holds enormous potential for logistical success. The problem is that many companies are satisfied with accepting the status quo, rather than actively seeking out the hidden opportunities that exist within the supply chain. The key lies in taking a more efficient approach to strategic sourcing and procurement management, one that turns logistics operations into value in the form of cost savings.

Here are 5 ways to uncover opportunities and recoup the money that’s left sitting in your supply chain:

1. Improve Your Supply Chain Processes

You can invest in new equipment or new personnel, but it is possible to discover hidden opportunities in your supply chain by simply looking at your existing processes. Your logistics employees follow standard operating procedures, but inefficiencies often arise when companies become complacent. The status quo is probably the biggest thief of resources in the supply chain, and even simple adjustments can result in gains once you have a look at where improvements can be made.

2. Assess and Monitor External Sources of Risk

The contingent workforce has become a big player in the supply chain as companies outsource more of their business operations, which means more risk lies outside the organization. It’s become necessary to look out for and mitigate risk from external sources that can compromise other players in the supply chain.

3. Determine and Respond to the Needs of the End User

Retailers are well aware that they need to please the customer who buys their product, but other players in the supply chain must realize that their future success also relies on end-user satisfaction. Manufacturers, distributors and logistics providers must appreciate the needs and motivations of the final customers in order to respond properly to fluctuations in demand. Every link in the supply chain should be working together to deliver and meet end-user expectations – or exceed them.

4. Optimize Flow-Paths

Take a look at the flow-paths in your supply chain and you’re likely to discover where improvements can be made. This will probably require you to actually get out a map and look at the most common routes within your logistical network. If there’s a more centralized location that makes sense, this is where you need to focus more of your operations.

5. Streamline Your Technology Landscape

Many of those in the C-Level Suite are surprised when they discover how many different IT systems providers and solutions they use within the supply chain. With disparate systems comes the likelihood of conflict in the technology and there’s often the need to duplicate effort. Multiple solutions also make it difficult and costly to keep up with changes in supply and demand. Companies that simplify their technology landscape with one application have a better view of the supply chain and can minimize costs.

It’s time to take a fresh look at your supply chain and realize that opportunities abound for cost savings and increased efficiencies. Strategic sourcing and procurement management initiatives can help you unlock the potential to turn information into insight.

This approach to getting more out of your supply chain may seem like a daunting task, but it’s not one you can avoid simply because you’re happy with the existing landscape. Fortunately, there are solutions available from software developers that are dedicated to helping you achieve your goals.

About Michael Wilson

Michael Wilson is AFFLINK'S Vice President of Marketing and Communications. He has been with the organization since 2005 and provides strategic leadership for the entire supply chain team. In his free time, Michael enjoys working with the Wounded Warrior Project, fishing, and improving his cooking skills.